|

|

It has been difficult to keep play/slack from developing in the clevis linkage that rotates the aileron torque tube. I have shimmed the pivot on the stick, but with time it needs additional attention. Clevis holes were oversized, and must be shimmed to fill the gap between the hole and the bolt. Fortunately, the cross tube that receives the bolt is a good sliding fit.

It has been difficult to keep play/slack from developing in the clevis linkage that rotates the aileron torque tube. I have shimmed the pivot on the stick, but with time it needs additional attention. Clevis holes were oversized, and must be shimmed to fill the gap between the hole and the bolt. Fortunately, the cross tube that receives the bolt is a good sliding fit.

This slack results in stick top free movement from side to side to about one inch. One may think this is of little significance, but when landing in a gusty cross wind, or flying on a rough day it is much nicer if one has to only exert pressure rather than displacement and pressure. It lets one keep ahead of the FireFly, and it requires less pilot energy to fly during unstable and turbulent conditions. |

The oversized 5/16 inch holes were drilled out to 29/64 inches. Using a Dremel tool, the holes were tapered larger to the outside. The amount a taper was determined by placing a 9/16 x 5/16 x 1/8 "O" ring on the 5/16 inch bolt and forcing it into the taper. Material was ground away until one could by hand almost force the head of the bolt flush to the outside of the clevis.

The oversized 5/16 inch holes were drilled out to 29/64 inches. Using a Dremel tool, the holes were tapered larger to the outside. The amount a taper was determined by placing a 9/16 x 5/16 x 1/8 "O" ring on the 5/16 inch bolt and forcing it into the taper. Material was ground away until one could by hand almost force the head of the bolt flush to the outside of the clevis.

|

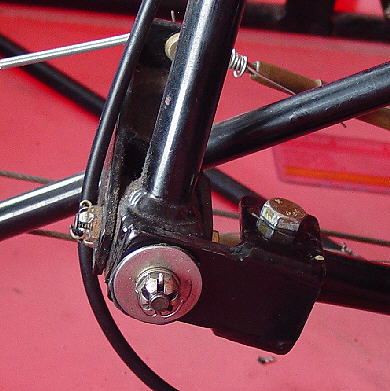

To finish seating the "O" rings, the whole works was assembled and the nut was run down to increase ring compression. If a ring did not push in to the inside of the clevis, more material was removed with a small rounded file. Then the process was repeated until what is seen to the left. The idea is for the rings to compress tightly around the bolt and to also compress against the cross tube ends that the bolt passes through. If this is done, there will be no clearance to produce any play or slack in the clevis to torque tube joint.

To finish seating the "O" rings, the whole works was assembled and the nut was run down to increase ring compression. If a ring did not push in to the inside of the clevis, more material was removed with a small rounded file. Then the process was repeated until what is seen to the left. The idea is for the rings to compress tightly around the bolt and to also compress against the cross tube ends that the bolt passes through. If this is done, there will be no clearance to produce any play or slack in the clevis to torque tube joint.

|

A brass shim stock bearing was placed over the pivot bolt.

A brass shim stock bearing was placed over the pivot bolt.

|

After everything was well greased, the clevis was reassembled to the torque tube, and the pivot pin. To keep the play from forming between the bottom of the clevis and the stick, nested "O" rings are placed around the pivot bolt. Then a flat washer is placed over them and the castle nut tightened to compress the "O" rings as shown in the top photo.

After everything was well greased, the clevis was reassembled to the torque tube, and the pivot pin. To keep the play from forming between the bottom of the clevis and the stick, nested "O" rings are placed around the pivot bolt. Then a flat washer is placed over them and the castle nut tightened to compress the "O" rings as shown in the top photo.

The advantage of this modification is that all joints are in elastic compression. If wear takes place there is sufficient spring force to take up the slack. |