|

|

|

Coolant System Pressure Release & Recovery Coolant Hose  The pressure pop off and return valve assembly was removed from the cap. It was replaced with a blank with a elbow mounted in the center. A hole was cut in the cap so that the elbow would protrude out through the cap. A nut was placed on each side of the blank to hold the elbow in place. To prevent the nuts from coming loose or any leaks, JB Weld was used on the threads and under the nuts.

The pressure pop off and return valve assembly was removed from the cap. It was replaced with a blank with a elbow mounted in the center. A hole was cut in the cap so that the elbow would protrude out through the cap. A nut was placed on each side of the blank to hold the elbow in place. To prevent the nuts from coming loose or any leaks, JB Weld was used on the threads and under the nuts.

|

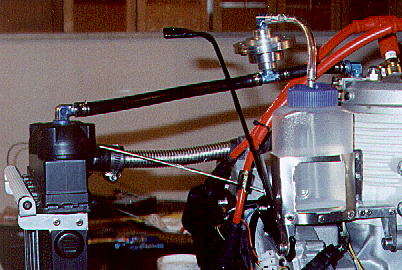

The pressure pop off and return valve assembly was mounted into a new assembly that can be seen connected between the head and the top radiator tank. The line coming from the top goes to the coolant recovery bottle. This bottle is a child's "Rubbermaid" drink bottle. The valve was removed and a quarter inch drill passed through the straw connection hole. A piece of quarter inch aluminum tubing was slipped into place and epoxied. Tygon tubing bridges the gap.

The pressure pop off and return valve assembly was mounted into a new assembly that can be seen connected between the head and the top radiator tank. The line coming from the top goes to the coolant recovery bottle. This bottle is a child's "Rubbermaid" drink bottle. The valve was removed and a quarter inch drill passed through the straw connection hole. A piece of quarter inch aluminum tubing was slipped into place and epoxied. Tygon tubing bridges the gap.

|

Coolant hose was made from one-half inch inside diameter stainless steel flexible gas tubing. To enable this tubing to with stand hose clamp crush forces, short sections of aluminum tubing were used. They sliced length wise and a small portion was cut away so that when the tube was crushed over the gas tubing it fit the gas tubing outside diameter. JB Weld was used to fill inbetween the stainless and the aluminum tubing. Two safety wire double twist hoops were made to hold the split aluminum tube gap closed until the adhesive had set.

Coolant hose was made from one-half inch inside diameter stainless steel flexible gas tubing. To enable this tubing to with stand hose clamp crush forces, short sections of aluminum tubing were used. They sliced length wise and a small portion was cut away so that when the tube was crushed over the gas tubing it fit the gas tubing outside diameter. JB Weld was used to fill inbetween the stainless and the aluminum tubing. Two safety wire double twist hoops were made to hold the split aluminum tube gap closed until the adhesive had set.

I started with rigid one-half inch copper, but switched to the stainless. Weight wise it was even, there are fewer joints and it is easier to shape. The surface area is much greater and this helps dissipate more heat. During hot weather and waiting in taxi queues, this may be important. |