|

|

|

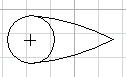

At 50 mph -> saves 0.18 hp These numbers are probably conservative, in that, at least half the push/pull tube is in the high velocity area swept by the propeller. In addition these fairings smooth out the air as it passes through the propeller, and have made a noticeable reduction in noise. The fairing profile was generated the same as was the wing strut fairings. After the foam pieces were glued to the push/pull tubes, they were formed and smoothened using a wall board sanding sponge. But instead of using chiffon fabric, organza was used. It is a polyester fabric but much lighter and thinner than chiffon. There are three advantages to using chiffon. It tears true from side to side, it has a thinner weave so it will hold less paint, and it is so light that one can wick it onto the surface using uncut latex paint. It is a little more expensive but it will provide the same surface wear property. To cover the push/pull tubes, a strip about four inches wide was ripped from the supply. During ripping the fabric will stretch a little and this makes it ripple along the edge. I tried to iron it out, but it was too much trouble, and so, I cut about 3/8 to 1/2 an inch away from each ripped edge. This leaves the smooth unstretched fabric. To get the fabric to stick to the desired surface is easy. Just put some latex paint on the foam surface and pat the fabric into the paint. A dab at the top, middle and bottom controls the fabric. This was followed by brushing on additional latex paint on the fabric where there is no paint. When all the fabric is saturated with paint, one can brush out ripples and air bubbles to the trailing edge of the fairing. The excess fabric meets at the fairing trailing edge and sticks together due to paint surface tension. After the paint dries, the excess fabric at the fairing trailing edge is trimmed away, and one more coat of latex paint is applied. |

One would not think there would be much value in fairing in the aileron push/pull tubes. But maintaining the same fairing shape as used on the struts one can calculate the following numbers.

One would not think there would be much value in fairing in the aileron push/pull tubes. But maintaining the same fairing shape as used on the struts one can calculate the following numbers.