|

|

Mounted a bright little light (50w halogen) in the nose cone to help others see the FireFly from a distance and in the airport area. Hopefully it will help counter the GA pilots who like to land straight in and down wind without using the radio.

Mounted a bright little light (50w halogen) in the nose cone to help others see the FireFly from a distance and in the airport area. Hopefully it will help counter the GA pilots who like to land straight in and down wind without using the radio.

This light was purchased from - All Electronics. |

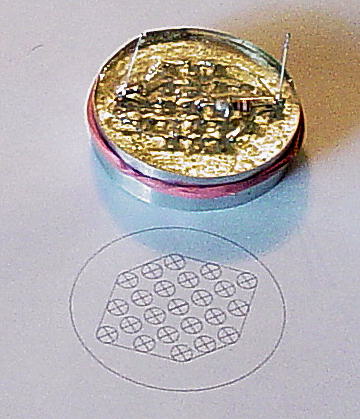

The original fifty watt light drew about four amperes of current. I have been noticing the bright red LED lights that are being used on new trucks and trailers, and I thought why not some clear white bright LEDs. I found some at the above named source, and they are a little expensive at two dollars a piece, but I bought twenty of them and mounted them in a hole pattern in some aluminum house flashing.

The original fifty watt light drew about four amperes of current. I have been noticing the bright red LED lights that are being used on new trucks and trailers, and I thought why not some clear white bright LEDs. I found some at the above named source, and they are a little expensive at two dollars a piece, but I bought twenty of them and mounted them in a hole pattern in some aluminum house flashing.

Wiring them in sets of four in series will drop 13.8 volts with out a voltage dropping resistor. Five series were then wired in parallel. The total current draw is about 0.1 ampere. |

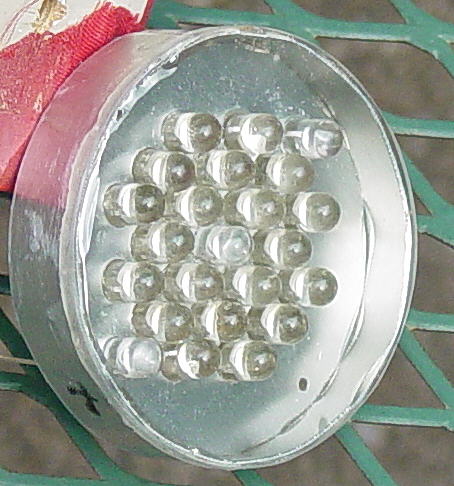

Acrylic cement was used to hold the LED's in place. After a series of four were glued and soldered, the assembly was tested to be sure that all LEDs were wired correctly by passing current through the assembly and checking that all LEDs lit up. Then the next series of four were glued and soldered, and the test repeated. By doing this one could unsolder and replace a defective LED with the least effort.

Acrylic cement was used to hold the LED's in place. After a series of four were glued and soldered, the assembly was tested to be sure that all LEDs were wired correctly by passing current through the assembly and checking that all LEDs lit up. Then the next series of four were glued and soldered, and the test repeated. By doing this one could unsolder and replace a defective LED with the least effort.

This photo shows twenty-three LEDs. To make this pattern work, I placed bright red LEDs in the middle and the outside of the middle horizontal row. |

The layout pattern was cut from another printout. The center was cut so that it would fit over the LEDs. Then tin snips were used to trim away the excess material.

The layout pattern was cut from another printout. The center was cut so that it would fit over the LEDs. Then tin snips were used to trim away the excess material.

A ring was made from a one-half inch wide strip of aluminum flashing and placed around the outsde of the assembly. Then the back side of the assembly was potted with epoxy to prevent vibration from breaking the solder joints. |

To finish up, a clear Lexan cover was glued to the front. Small holes were drilled through the epoxy along the top and bottom edges to vent the chamber inside.

To finish up, a clear Lexan cover was glued to the front. Small holes were drilled through the epoxy along the top and bottom edges to vent the chamber inside.

The assembly was mounted in the nose cone as a replacement for the fifty watt lamp. |